Are you familiar with green manufacturing? It’s an idea that’s been around for quite some time, and recently it’s become more popular as the benefits of eco-friendly manufacturing efforts have continued to grow. Here’s a look at what green manufacturing is, how it can benefit manufacturers - as FASTER - and consequently favor our clients – as you.

What’s green manufacturing?

At FASTER, we look at green manufacturing in two different ways:

1) The manufacturing of “green” products, particularly those used in lab tech and clean air technology equipment of all kinds.

2) The “greening” of manufacturing – reducing pollution and waste by minimizing natural resource use, recycling and reusing waste, and reducing emissions.

In this post we’ll examine the first aspect; we’ll deal with the second topic in another post dedicated to our new factory and its green innovations.

FASTER’s laminar-flow, cytotoxic drug safety cabinets and microbiological safety cabinets have an ultralow environmental impact, by utilizing:

- Certified ‘low pressure-drop’ H14 HEPA/ULPA filters providing up to 30% saving on power consumption.

- Electronically controlled motor-blower with automatic pressure-drop compensation

- 99% of recyclable components

- Innovative technologies such as the new ECS® microprocessor

- Air cleanliness in Class ISO 3, according to ISO 14644-1

Let’s get more technical

Most of FASTER’s Biological Safety cabinets and fume cupboards host ECS® Eco Controlling System. What’s that? It’s a microprocessor employing the latest innovative methods of integrated management of all principal functions of ventilation and filtration for declining pressure drops and restoring power balance.

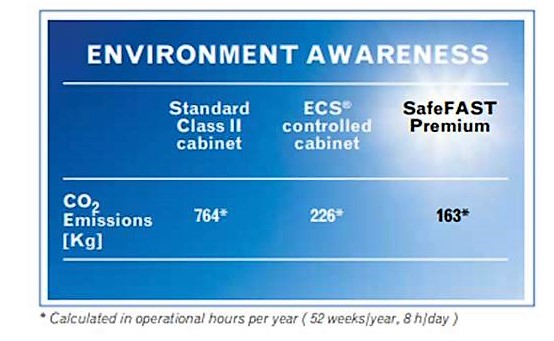

Combining the use of AC motor-blower and certified low pressure-drop H14 HEPA/ULPA filters, the ECS® controlling system optimizes power consumption, reducing CO2 emissions into the environment.

The technology inside our total exhaust chemical fume hoods, like ChemFAST Sharp and Classic, allows our clients to make energy savings just finding a favorable compromise between air-conditioning consumption and the most difficult pollutant removal rates.

ChemFAST Premium has been engineered to combine molecular filtration with the aeraulic working principles of recirculation and exhausting: a brand new technology of hybrid chemical fume cupboards developed by Faster to get an energy consumption decrease by 80%. Moreover, even the small quantity of air used is always filtered before being exhausted into the environment.

We know we can do even more. Our R&D dept. is studying other innovations to make our technologies even greener.

Next time, we will address the topic of green production by entering the brand new FASTER factory in Ferrara, Italy. Follow us here or get our updates on FASTER LinkedIn page!