Speed up delivery times, guarantee better equipment customization options, 100% supervise the quality process, minimize waste and environmental impact: these are the reasons that led FASTER to invest in a new, innovative production plant for the production of Lab Equipment and Industrial Systems.

THINK LEAN: DO MORE WITH LESS (WASTE)

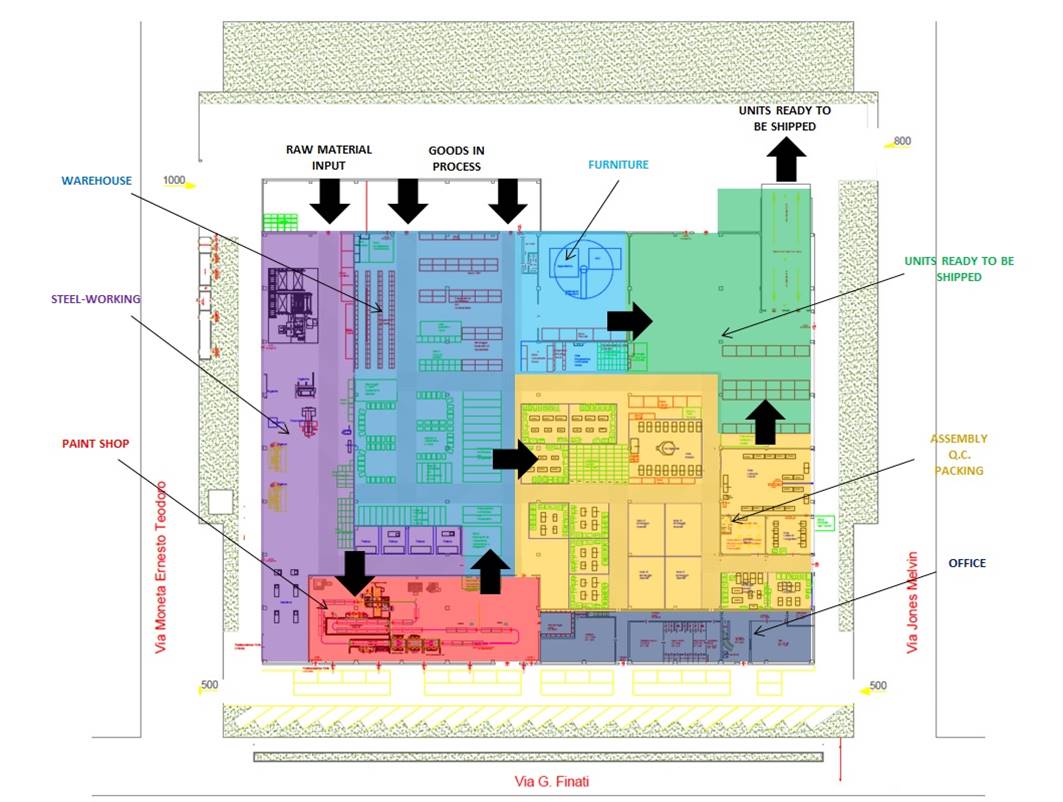

Located in the industrial area north-west of Ferrara (Emilia Romagna region), the factory was organized in collaboration with the Engineering Department of the University of Bologna, in accordance with the principles of Lean Thinking.

What’s Lean Thinking? Lean Thinking represents an organizational methodology aimed at giving added value to the products and/or services of an organization, through an innovative analysis of the processes and the consequent reduction of waste. The goal of the Lean approach is to produce more with less consumption of resources, thus obtaining an important competitive advantage to be able to respond more effectively to customer needs.

The result is a structure extended over 10,000 square meters designed to optimize the organizational flow and rewarded with the Lean Health Award 2018.

MORE SPACE, MORE INNOVATION, MORE EFFICIENCY

All the surfaces of the production areas are significantly increased compared to the previous plant: + 65% Steel working area, + 180% warehouse area, + 168% assembly area, a brand new cleanroom for technology test, + 135% office area.

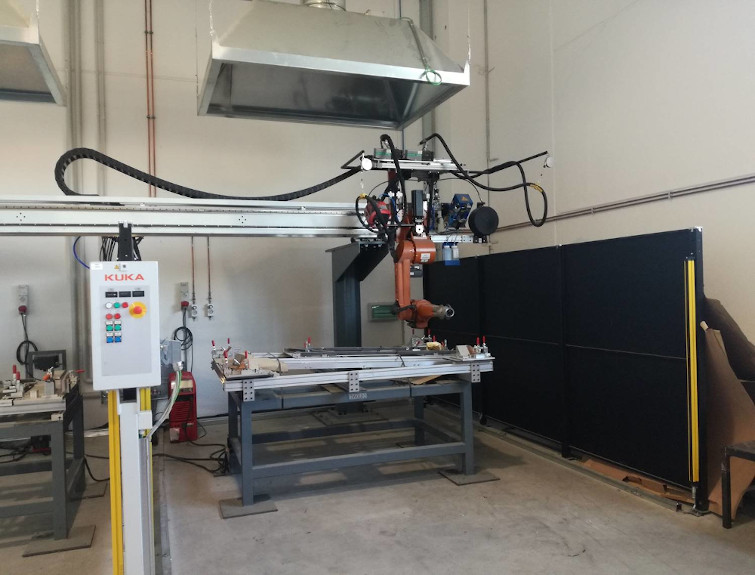

Process innovation has been accompanied by technological innovation, with a significant investment in new equipment to cover the entire process with internal production:

New laser machine for cutting iron and stainless steel sheets

New folding machine for bending iron and stainless steel sheets

New deburring tool to remove burrs from iron and stainless steel sheets

New welding robot for fully automated welding activities

New paint shop for 100% in-house production

The technological renewal and the new organization of the spaces are guaranteeing greater productivity. This has prompted the company to increase its number of production workers, focusing on increasingly specialized personnel. The factory currently employs 80 employees, including production, administrative and technical personnel.

If you wish to visit the Faster factory, contact us and we will open the doors to the most innovative Lab equipment production plant in Europe: This email address is being protected from spambots. You need JavaScript enabled to view it.